5 Client Carbon Commitments

The UK construction industry and builds and maintains the infrastructure that we all need as we go about our daily lives and is vitally important for the UK’s economic prosperity. However, construction is also a significant contributor to the UK’s carbon emissions, and it is time for us to take action.

CO2nstruct Zero is calling upon clients to act with the launch of our Five Client Carbon Commitments – simple, practical steps that organisations can take to show how they are reducing their carbon emissions and by when.

The Five Client Carbon Commitments are:

Nine organisations have taken the bold step to be the first to sign up – we welcome the leadership shown by Anglian Water, Heathrow, the Lower Thames Crossing, National Highways, Northumbrian Water, Transport for London, Sellafield Ltd, Scottish Water and The Environment Agency – and invite other organisations to join them.

The Commitments

Five-point plan to transition construction to net-zero

We will:

1. Procure for low carbon construction and provide incentives in our contracts

2. Set phase out dates for fossil fuel use

3. Eliminate the most carbon intensive concrete products

4. Eliminate the most carbon intensive steel products

5. Adopt PAS 2080, Carbon Management in Infrastructure, as a common standard

1. Procure for low carbon construction and provide incentives in our contracts

What this commitment means:

An organisation must set the date by which:

- Low carbon construction will be part of the criteria for the awarding of its contracts

- Incentives to reduce carbon emissions from construction will be included in new contracts

Why this commitment is important:

The opportunity to signal demand for low carbon construction is in the way that we buy. If low carbon ambition and requirements are not part of a construction contract, they are unlikely to happen.

About contracts:

Procurement and contracting approaches will vary between clients.

Low carbon can be incorporated into any construction contract.

Some standard form contracts now have optional carbon incentive clauses so there is no need for new drafting. E.g. NEC4 X29

2. Set phase out dates for fossil fuel use

What this commitment means:

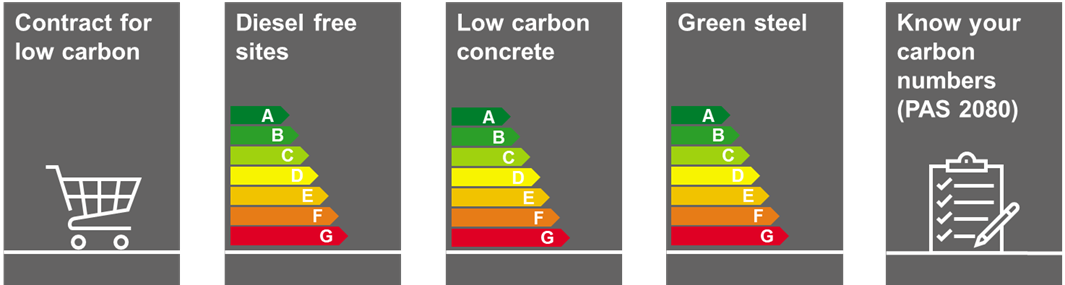

An organisation must set the dates by which its construction sites will attain the levels on the diesel free sites scale. The commitment relates to the use of equipment on construction sites.

Why this commitment is important:

It is estimated there are over 300,000 items of Non-Road Mobile Machinery (NRMM) in use across the UK construction sector. These include excavators, bulldozers, cranes, haulers, and many other machines. Typically, they are powered using diesel engines. Many are considered “hard to abate”, due to very high-power demand and duration of use, compared with the more common applications of diesel engines in road transport. Most construction NRMM are manufactured solely for use in this industry. Fossil free and zero emissions NRMM will only be developed and manufactured if there is clear demand for these products.

About this scale:

3. Eliminate the most carbon intensive concrete products

What this commitment means:

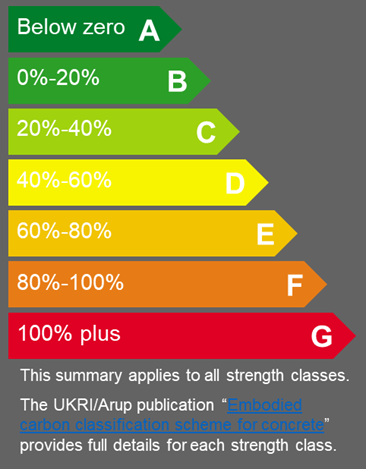

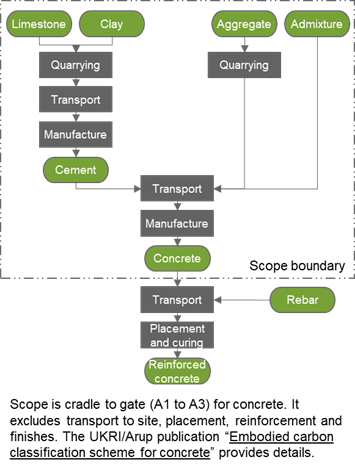

An organisation must set the dates by which its construction sites will attain the levels on the low carbon concrete scale. The commitment relates to all concrete applications.

Why this commitment is important:

Concrete is the world’s most used construction material. It is responsible for about 8% of global emissions. The cement within concrete is responsible for most of the carbon emissions associated with concrete. This is due to the high levels of energy used and the chemistry of breaking limestone down from CaCO3 to CaO during cement manufacture. The concrete and cement industry must invest heavily to reduce the carbon intensity of the products in the market, and this needs clear client demand for low carbon.

Innovate UK have introduced a mechanism to support clear client demand, helping to unlock investment and insurance products that can accelerate the development and deployment of low-carbon concrete solutions. Learn more here.

About this scale:

4. Eliminate the most carbon intensive steel products

What this commitment means:

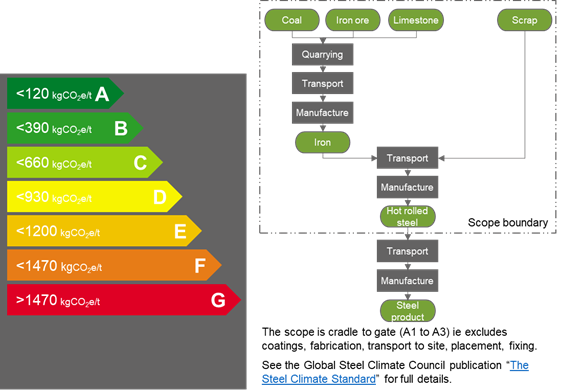

An organisation must set the dates by which its construction sites need to attain the levels on the green steel scale. The commitment relates to construction products like the reinforcement used in concrete and structural steel.

Why this commitment is important:

Construction is responsible for about half of global demand for steel. Iron and steel account for about 7% of global emissions. This is largely due to the use of coke to provide heat and as a reducing agent in the manufacturing process. The steel sector must invest heavily in alternative manufacturing processes to reduce the carbon intensity of the products in the market, and this needs clear client demand for low carbon steel.

About this scale:

5. Adopt PAS 2080, Carbon Management in Infrastructure, as a common standard

What this commitment means:

An organisation must set the date by which it will achieve independent verification that its management system complies with PAS2080.

Why this commitment is important:

It creates a consistent framework for carbon accounting and management, providing a common language for the sector during transition to net zero.

About the Standard:

PAS 2080:2023 specifies requirements for the management of whole-life carbon in buildings and infrastructure.

It has been sponsored in the UK by the Construction Leadership Council, Institution of Civil Engineers and the Green Construction Board.

It is available free of charge and there are a number of independent bodies that can verify a management system against the standard.

Why sign up to the five-point plan?

The UK government has legislated for Net Zero by 2050 – the construction sector must change fast to be part of the solution and not part of the problem.

Our sector is critical to the success of the country’s economy, contributing just under 9% Gross Domestic Product annually. We build and maintain the infrastructure on which society relies, but we are also a big contributor of carbon emissions that are causing climate change.

There is a huge amount of work happening across the sector to tackle our Net Zero challenge, but we need to bring that work together and – as leaders of the sector – act and drive change by being bold. We can do this by using our procurement to drive out carbon; embracing new and innovative materials; changing how we power plant and machinery; and implementing new methods and ways of working.

We have a moral responsibility to address this challenge head on and to set the standards needed to lead the sector into a Net Zero future. By working together as an industry to make real changes – reducing our carbon footprint by embracing cleaner, greener and more sustainable ways of working – we have the potential to make an enormous, positive difference for a bright, green future for us all.

What is the five-point plan?

- The five-point plan is a client led approach to creating clear demand for transition to net zero within the construction industry

- Each client will make five simple commitments

- The framing and communication of the commitments is consistent

- The level of ambition is up to each organisation

- The five-point plan was launched in the spring of 2024 at an Executive level event, co-sponsored by the Construction Leadership Council, Infrastructure Client Group, Infrastructure and Projects Authority, and the Major Projects Association.

Hints & Tips

General considerations for adoption of the five-point plan

- The five-point plan is about client leadership

- It has been developed to be intuitive and easy to communicate

- It provides a consistent frame of reference so that the whole industry can use the same language

- There is some flexibility in the implementation for individual organisations

- You will need to create your own rules about how you monitor implementation in your organisation and how you treat exceptions

- Try to keep the intent in mind when making these decisions and ask if they are reinforcing your leadership on net zero or whether they risk undermining it

- Do publish updates on your progress against your commitments

- Set a review frequency

- Long enough to provide some confidence and stability to the market

- Short enough that you can flex to meet the needs of your business

- Perhaps in line with a five-year regulatory cycle or other business rhythm

- Add other commitments to suit your organisation / strategy

- The five-point plan works for all infrastructure organisations but is certainly not limiting

- Other materials may be of specific interest to your organisation e.g. National Highways will be setting a similar scale and commitment for asphalt

- There are plenty of other aspects of the transition to net zero that you may want to address in your own public commitments e.g. the Carbon Reduction Code for the Built Environment

- Just make sure the five are included!

1. Procure for low carbon construction and provide incentives in our contracts

Every organisation will embed the transition to net zero into their contracts in their own way. Here are some things to think about:

- Scope / requirements

- Include a requirement for PAS2080 compliance

- Include your carbon intensity limits steel, concrete and other materials

- Include your phase out dates for diesel

- Consider how you will verify that your standards are being met

- Environmental Product Declarations (EPDs) are becoming widely used and understood, other approaches may be possible

- Consider chain of custody and matching of EPDs to products

- Consider other elements of good practice in carbon reduction e.g. use of the Carbon Reduction Code for the Built Environment

- Procurement

- Include low carbon within your selection criteria

- If the data is available, be specific about overall emissions limits and ambition for a contract

- Commercial

- Use incentives

- Standard form contracts now have optional carbon incentive clauses so there is no need for new drafting. e.g. NEC4 X29

- Design

- Contracts and commercial incentives can be a great way to encourage carbon efficient design, including the “avoid” and “switch” steps, as well as the “improve” step

- The diesel, concrete and steel commitments drive a reduction in the carbon intensity of key products, part of the “improve” step in the PAS 2080 hierarchy

2. Set phase out dates for fossil fuel use

- Application of the scale

- The scale targets carbon, you are likely to need other requirements to address other issues associated with NRMM e.g. specify Stage V engines to manage air quality

- Consider applying the same approach to on-road movements to and from your construction sites

- Biofuels

- The sustainability of the feedstock used in biofuels can be hard to verify. Consider using more than one verification system and limiting to sourcing within trusted markets.

- There is limited global availability of sustainable biofuels.

- Oslo City

- Oslo City has world leading policies on diesel free and zero emissions construction sites and has had significant success in transition, ahead of general market availability of zero emissions construction NRMM

- Reference points

- 2030 is credible for zero emissions with several European equipment manufacturers projecting availability across multiple lines.

- 2030 is the publicly declared ambition for National Highways to achieve zero emissions construction sites.

- Big infrastructure clients are likely to need to be at zero emissions by 2035 to deliver the existing CLC commitment of 78% diesel free for the whole industry by 2035

3. Eliminate the most carbon intensive concrete products

- Setting near term limits:

- The Mineral Products Association (MPA) has published an “Embodied carbon of concrete – Market Benchmark”, developed by the Low Carbon Concrete Group, in the UK

- Overlap this data on the scale to understand where the market is today

- The middle of the market is about D for most concrete grades

- Setting long term ambition

- Any existing corporate net zero commitment date is likely to be your backstop for achieving “A” e.g. 2040 for National Highways

- In the absence of any other public commitment, 2050 has to be the minimum level of ambition!

- The bits in between

- C is achievable today using high levels of GGBS as cement replacement. This is likely to become a scarce resource as steel works at Port Talbot and Scunthorpe shut down their blast furnaces, leading to greater adoption of alternatives like calcinated clays.

- A & B are likely to require breakthrough technology like CCS or approaches being pursued by Cement2zero and Brimstone

- There are plenty of existing industry net zero publications available. The MPA have lots of resources on their website. Individual suppliers have also published their own net zero trajectories.

- Consider where you want to position your organisation, as a leader or follower.

- Remember that this is a maximum carbon intensity

- It does not limit your ability to do better in some applications of concrete

- Make sure that your contracts support your supply chain in doing better where they can!

4. Eliminate the most carbon intensive steel products

- Long and flat steel

- Consider differentiating between the two in setting your ambition

- Long steel is used to make reinforcing steel for concrete and in other construction applications like rails and I-beams

- In Europe, it is predominantly made in an Electric Arc Furnace (EAF) and has a relatively low carbon intensity

- Flat steel is used in other construction applications

- In Europe, it is typically made in a blast furnace and has a much higher carbon intensity than steel made by EAF

- Setting near term limits:

- UK and Europe sourced re-bar could meet a “B” or “C” today

- UK sourced flat steel is likely to be “G” until the Tata and British Steel plants transition to EAF

- There is likely to be availability of European sourced flat steel at “D” or better in the near term

- Setting long term ambition

- Any existing corporate net zero commitment date is likely to be your backstop for achieving “A” e.g. 2040 for National Highways

- In the absence of any other public commitment, 2050 has to be the minimum level of ambition!

- The bits in between

- “C” or even “B” should be achievable in flat steel, using a high recycled content and EAF

- This is already the case for re-bar / long steel

- Tata and British Steel both projecting availability of a flat steel product with high recycled content and EAF before 2030

- H2 DRI or equivalent technology will be needed to achieve “A”

- Sourcing

- It is likely that your steel is sourced through a fabricator or other intermediary, and not directly from the steel producer

- Ask your suppliers where they source from and what other options there are

- Ask if it is possible to lower the carbon intensity of EAF produced steel by using renewable electricity or increasing the recycled content

5. Adopt PAS 2080, Carbon Management in Infrastructure, as a common standard

- Most organisations should be able to develop or update their management processes to align to PAS2080 within about 12 months.

- Independent verification reviews are best booked well in advance.

- Consider how much of your supply chain should also align to the PAS principles to make implementation effective without being over-burdensome

- PAS 2080 supports system wide planning for carbon reduction, following a hierarchy of “avoid, switch, improve”.

Example Commitments

Example of commitments by current infrastructure clients:

More Information

Contact Info

Stuart Young MCIPR

Head of Stakeholder Engagement & Management

Construction Sector Relationship Manager

Communications Director for Construct Zero

T: 0782 6948935

E: Stuart.Young@businessandtrade.gov.uk

More Information

- Click here to learn more about the Construction Leadership Council and the latest news/events happening.

- Construction Leadership Council: Overview | LinkedIn

- https://twitter.com/ConstructionCLC

- https://www.youtube.com/@ConstructionLeadershipCouncil